It has been a long time between drinks – ah sorry, I meant to say it has been a long time since I posted anything on this Blog.

I had thought Raymond and I would have achieved a great deal on the layout in The Shed but such was not to be. Raymond has had a months holiday starting at the beginning of August and I took a week’s holiday as well during Ekka Week. Raymond had great plans but they didn’t eventuate.

The almost completed section along the left-hand wall.

The almost completed section along the left-hand wall.

During his first week he worked on trying to fit a Lok-Sound DCC chip and speaker to an AMS model of No.50 the Rio Grande narrow gauge 0-4-0DM. Although the model looks deceptively large when Raymond dismantled it there was just nowhere to fit the decoder let alone the speaker. He had the decoder specially programmed with a Caterpillar diesel engine sounds which the original locomotive had fitted. Back to square one! Raymond has reassembled the loco and put it back in the display case muttering to himself.

During my week off we fitted the double-slotted metal brackets to the right-hand side wall of The Shed.

"Missed it by that much". Notice all the pencil marks. Even using a laser stud finder it is still difficult to determine the exact location of a stud.

"Missed it by that much". Notice all the pencil marks. Even using a laser stud finder it is still difficult to determine the exact location of a stud.

The brackets and L-girders completed on the right-hand wall. The baseboard along here withh be about 2 ft 3 ins wide.

The brackets and L-girders completed on the right-hand wall. The baseboard along here withh be about 2 ft 3 ins wide.

Around the corner and along the back wall. There will be ajunction station mid-way along the right- hand wall with a short mining branch heading towards the back wall and a major mining branch heading in the opposite direction.

Around the corner and along the back wall. There will be ajunction station mid-way along the right- hand wall with a short mining branch heading towards the back wall and a major mining branch heading in the opposite direction.

We made the L-Girder for the right-hand wall and fitted those to the metal brackets. Although we followed the same method of construction as the left-hand wall we found that all the brackets were not dead level so we had to shim the L-girders in a few places. This was most frustrating as we asked ourselves “How did this happen?

I had always intended that the section of layout along the back wall of The Shed would combine in a scene the upper and lower levels. The upper track would cross the lower on a high trestle while the lower track would traverse a deep river gorge. As it turns out we decided that the brackets on the right-hand wall should follow around for a couple of brackets on the back wall so as to allow the curve to come around fully to track across the back of The Shed. We decided to do this on the right-hand wall as well with the brackets continuing probably for just over a third of the way across the back of The Shed. This will allow for a mining branch to terminate at a couple of mines in the back right-hand corner and across the back wall of The Shed.

We installed the brackets for these two sections at the end of my week’s holiday. We also made and fitted the L-girders for this section. I was sitting down at my work bench looking back down The Shed with a satisfied look on my face that we had at least achieved something. But hold on “We have a problem Houston”. My thoughts turned to the future air-conditioning unit on the back wall of the shed. Would the installer be able to install that heavy unit working across the top of the 2 feet wide baseboard framework (and potentially track and scenery). I e-mailed by friendly electrician sending him some images. He thought not. “Could we build a section of the layout below where the air-conditioner was to be installed?” or “Could we stop work until the air-con was installed?”

This is what I saw when I was contemplating our achievements or lack thereof. The gap is where the high bridge/river gorge scenery will be installed while the air-con unit will be installed high up on the back wall.

This is what I saw when I was contemplating our achievements or lack thereof. The gap is where the high bridge/river gorge scenery will be installed while the air-con unit will be installed high up on the back wall.

The gap again.

The gap again.

We have a problem with the power supply to the house from the street power box. Our builder used the minimum size cable allowable which did not take into account any future requirements (such as air-conditioning). Our electrician is going to install heavier cabling – when we can afford it. In the meantime he asked – “Do you have any other air-conditioning in the house?” Answer “No”. Well he says you can install the air-con unit now and even use it – just make sure your wife doesn’t use the clothes drier in the laundry or oven in the kitchen if you are using the air-con in The Shed.

We don’t want to have the hassle of building a removable section of the layout as it would be the bridge section which, besides the delicate trestle bridge, would include all sorts of scenery and track connections as well as the necessary wiring connections. We do not really want to suspend work on the layout pending the laying of the heavy-duty cable from the street to the house and then installing the air-con. The cost of the air-conditioner I have been advised that we will need is $4,000 installed due to the size of the floor area of the shed let alone the cost of digging a trench and installing a heavy cable from the street to the house.

It looks like work on the On30 layout will need to be temporarily suspended pending at the very least, the installation of the air-conditioner. However, the budget is overspent at present so it will be a few months before we can afford to get the air-con installed. If we do go down this path we will have to make some rules regarding the sue of the air-con and household appliances.

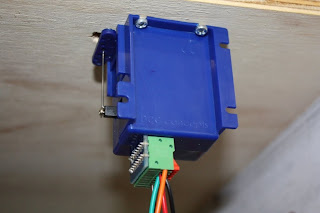

Since we have come to a standstill on the On30 layout, I decided we should start work on Raymond’s N Scale layout in the garage. This will be the On30 layout that Raymond and I started building (but never finished) which was meant to go around my car. We started on Saturday 27 August by dismantling a section of the baseboard and framework that we had built previously along the right-hand side of the garage wall. We narrowed a section down so it is protrudes into my car space for the same distance along the length of that side of the garage. This will make it easier to open my car door although the original baseboard did allow me adequate access. The reduction in width has just made it so much easier.

The section of the original On30 layout which I wanted narrowed.

The section of the original On30 layout which I wanted narrowed.

The same section from another angle.

The same section from another angle.

On Sunday, 28 August I completed the decking on top of the rebuilt baseboard and started dismantling the yard of the On30 layout. We will get quite a few points out of this as well as quite a deal of Peco On30 Flextrack.

The rebuilt section looks quite neat now if I do say so myself.

The rebuilt section looks quite neat now if I do say so myself. Dismantling the yard on the original On30 layout.

Dismantling the yard on the original On30 layout.

More salvage work on the old On30 layout. I am not sure how long it will take Raymond to build the N Scale layout but I sure that PK is hoping it is sooner rather than later.

More salvage work on the old On30 layout. I am not sure how long it will take Raymond to build the N Scale layout but I sure that PK is hoping it is sooner rather than later.

Well this is Raymond’s last day of his annual leave. He wonders where the time has gone? Back to work Monday.