Time really flies and I know that we have been totally slack as there has been no progress on the layout construction and little progress in other areas other than Raymond’s purchase of more rolling stock mainly for the non-existent Garden Railway.

My last post was on the 29 April – was it really that long ago?

The AMRA Brisbane Miniature Train Show was held over the Labour Day Weekend in May. I volunteered to do security duties and spent the Friday keeping an eye on things during the set-up and then I spent each of the three days the show was opened watching over the displays and helping wherever necessary. This was the last show held at the RNA Showgrounds with a pavilion at the Doomben Racecourse selected as the venue for 2013. The change of State Government has meant the transfer of the three day-Labour Day Weekend from May to a date later in the year to better spread out public holidays in Queensland. The 2013 AMRA Show will take place over two days instead of three.

The Tuesday Nighters came over to The Shed on the 1 May and again on the 29 May and finally for 2012 on the 11 December. The AMRA NG SIG Group visited The Shed on 17 July and again on 18 December. Unfortunately little had changed on our layout between those visits but everyone still had a great time with lots of talking and many suggestions as to how we could get going again on layout construction.

Craig (Cassino) phoned me early on the 3 June and invited me to pay a visit to Toowoomba with him to see the DDMRC train show. Geoff was going to be there with his Splitters Swamp Creek Layout. It was a good trip and like Craig, I had not been to the Toowoomba Show for quite some years. It was good catching up to have a yarn with many people I knew.

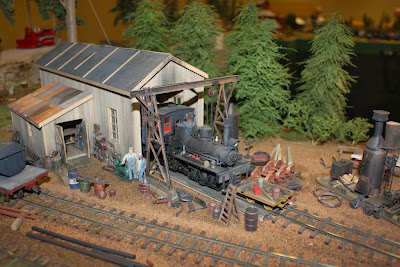

A scene on Geoff's Splitters Swamp Creek layout at the Toowoomba Show.

The trophy awarded to Splitters Swamp Creek layout at the Toowoomba Show.

Work issues took up a good deal of my spare time in the second half of 2012. I was sent to Mackay for a week to undertake significance assessments of the Mackay Heritage Railway during July. I also managed to get a few photographs around the local cane railway networks. It had only just stopped raining just before my arrival in Mackay and the mills did not start crushing again until several days after my arrival so I managed to get much of my Museum work done in the first few days. The resultant Museum report took a lot of time to prepare mainly taking up another weekend.

Museums & Gallery Services Queensland invited me to become an assessor on their National Museums Standards Program. This involved several visits to Bundaberg as I was asked to undertake the assessment of the Australian Sugar Cane Railway. My first trip involved a return journey on the Bundaberg Tilt Train departing on Friday and returning on the Monday. The second trip was by plane on a Saturday returning by car on the Sunday night. The final trip was for a week which again involved a return trip on the Bundaberg Tilt Train during the last week in November. This was more of a short holiday so I paid for the journey although there was some Museum work involved. During this last trip I undertook some oral history work with sugar industry staff for the Museum and I also had time to take some photographs of the cane railway systems around Bundaberg.

I had been purchasing timber for the construction of the layout baseboard a section at a time but delivery charges would add another $100 or so to the cost so I determined that it would be better if I worked out my timber requirements for the remainder of the layout and have it delivered in one go probably saving a couple of hundred dollars. I spent some of my spare time during the last half of the year drawing and redrawing the layout and working out the baseboard boundaries. I then started trying to estimate the timber requirements but could not make up my mind. We had visited Darren (Tuesday Nighters) and seen his Nimmitabel Extension layout back in May and I was impressed with his methods of baseboard construction. I had used a variation of L-Girder construction for the top deck of the layout on three sides of the room but felt that this would be unsuitable for the lower deck due to the significant depth of the supporting framework. The upper deck could only be supported from the walls of the room and obviously could not have any supports along the front edge whilst the lower deck could be supported by legs in direct contact with the floor at both the rear of the layout and also along the front edge.

Darren has been one of the Tuesday Nighters offering constructive, and more importantly, practical suggestions for our layout to progress. He may be a New South Wales modeller (we forgive him for that) but he is a keen model railroader and a good friend. I discussed with him many times his construction techniques which I know some of the other guys use as well.

I had set down some goals that I thought we might be able to achieve over the Christmas break and discussed these with the Tuesday Nighters when they visited on the 11 December. I said that I wanted to buy a drop saw which seemed to me to be an essential piece of equipment for the construction of the remainder of our layout. I also indicated I hoped to buy all the timber needed but I still hadn’t worked out what was required. I did know that I would not need any more of the 45 X 19 mm (2” X 1”) as I already had a number of lengths if I found a requirement for some. My main purchase would be 90 X 19 mm (4” X 1”). I had set myself a target of building the lower deck on the right-hand side of The Shed before starting the new baseboard extensions.

I sent an e-mail to the Tuesday Nighters on the 22 December outlining my thoughts and inviting comment on these. The guys responded positively so I started looking at drop saws and looking more seriously at our timber requirements.

On Thursday 27 December I lashed out and purchased a Bosch Mitre Saw (drop saw) and a finer blade (more teeth to give a finer cut than the standard blade that comes with the saw). Later that day, Darren phoned and asked if I had worked out my timber requirements yet? I hadn’t! He indicated he could deliver the timber the next day at the right price so I set to and worked out what I thought I needed. After a couple of false starts and a few more phone calls to Darren I had settled on an order with him – 40 lengths at 5.4 metres each of 90 X 19 mm.

First thing Friday 28 December I went down to Bunnings and purchased the Bosch Mitre Saw Work Bench that suited my Mitre Saw purchase. Later in the morning Darren turned up with eight 5.4 metre long bundles of 90 X 19 mm dressed pine which we unloaded into the shed. Darren spent some time with Raymond and I explaining how we should go about setting out the timber, undertaking the necessary measurements, cutting the timber then drilling, countersinking and assembling the baseboard framework. He was adamant that we should do this work on the garage floor as there was a large flat area. Darren pointed out there were two advantages over using the floor in The Shed. Firstly, we would minimise wood shavings from drilling and screwing and above all the surface would give us a firm surface making it easier to get everything square unlike the carpet in The Shed which would “give” making getting a square structure almost impossible. Raymond and I decided that we could use my wife’s side of the garage as this meant it was directly in line with the laundry door through the pergola and straight in through the door to The Shed. This was a brilliant idea on our part, except SWMBO did not go out often when we were home but did go to church for a couple of hours every Sunday morning. We reckoned that we could measure and cut the timber framing for each section of the baseboard framework Saturday afternoon then assemble it Sunday morning and have it into The Shed before she came home.

We could, of course move her car outside the garage when we wanted to do this work but it is a relatively new car and the fuel injection system requires the engine to be run for quite some time before it is turned off again otherwise it will “flood” and the car is almost impossible to start again. We have had the RACQ out twice to start it after these events.

Over the weekend of the 29 – 30 December, Raymond and I assembled the Bosch Mitre Saw which I have christened Son of Beast. It is not as frightening as The Beast (a Ryobi Bench Saw) which some of you may remember I purchased during the period when we were insulating and lining the shed with plasterboard. The Beast was really needed only for one short job on this project and I subsequently sold it for less that half price as I did not see any further need for it. The need for a drop saw was now, however, very much greater. It would be ideal for cutting the 90 x 19 mm and 45 X 19 mm timber to the required length and would also give us the flexibility to cut angles where required.

The Beast when it was being used during the finishing stages of The Shed.

Son of Beast - the Bosch Drop Saw I purchased from Bunnings. (Photograph – Son of Beast)

We have set Son of Beast under the pergola just outside the shed. On New Year’s Day, the first day of 2013 we christened Son of Beast and, other than a couple of mistakes with two lengths of timber shorter than intended it worked brilliantly. We ended up with two 3600 mm long pieces and seven cross pieces. The two long pieces were cut exactly to length and the final seven cross pieces were all exactly the same length and everything was cut square. If I had done this with my hand-held power saw I would have cut the timber to all different lengths and some would have curved ends instead of being square. Fantastic!!

I have yet to acquire the 70 X 35 mm timber for the legs of the bottom deck but Darren has offered to help there too. Thanks Darren.

We had planned to assemble the first baseboard framework this weekend when Pauline went to church. However, Raymond and I have been told we have a special family barbecues coming up in a couple of weeks so we have had to spend the time mowing the grass, making a trip to the dump and getting ready for a rubbish skip next weekend whence we are disposing of a lot of old furniture, mattresses and sundry junk. Sunday afternoon, we decided to move my car out of the garage and build the baseboard frame there. This was not quite as accessible but within half an hour we had this first panel built and we have the photo to prove it.

The first baseboard framework panel.

I hope to be able to give more details on what has happened in the latter half of this past year and also more especially list some more progress on the layout next week.